Necessary of Blower Maintenance

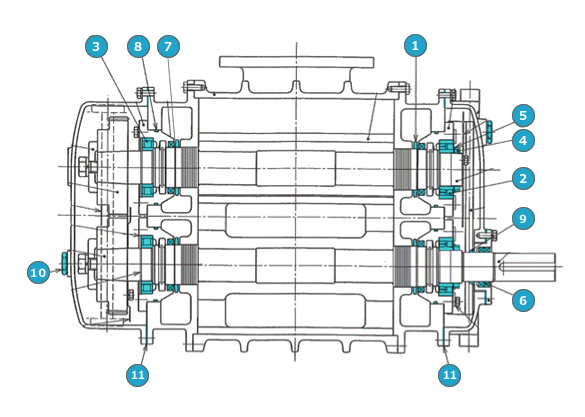

Although the blower looks like a lump of iron, it has lots of spare parts inside, such as shaft bearing which is necessary for rotating, and oil sheet which can prevent oil from laking to the outside.

These parts rub and deteriorate gradually due to temperature rise, friction, and viberation caused by the rotary motion.

The blower will deteriorate over time even when it is not operated.

If blowers keep operating with deteriorated parts, the sudden trouble and breakdown will cost a lot for the repair.

Furthermore, blowers are necessary for plant operation, a long-term shutdown can generate large losses.

The best method for clients to avoid these kinds of troubles is "Regular Maintenance".

To use blowers comfortably and safely for good, please use ITO's maintenance services.

ブロワの消耗部品一覧

| 1 | フリンガ | | 2 | ベアリング(1) | | 3 | ベアリング(2) | | 4 | ベアリングナット

| 5

| ベアリング座金 | 6

| オイルシール(2) |

| 7

| オイルシール(1) | 8

| Oリング | | 9 | Vリング | | 10 | オイルゲージ | 11

| シートパッキン | 12

| Vベルト

|

|

Besides shaft, blowers are composed of lots of rubber products such as oil seal. It is necessary to replace these consumable parts during maintenance.

Overhaul Construction

1.Before Construction

|

2.After Disassembly

|

|

3.SUS Coated After Cleaning(1)

|

4.SUS Coated After Cleaning(2)

|

|

5.Spare Parts Replacement

|

6.Establishing

|

|

7.Completed

|

|

|

Example for failing to maintain

Value of maintenance

Although the specifications and uses are different, maintenance can identify the operational situation of equipments and avoid the risk of malfunction, which will keep performance and lengthen the lifespan of blowers.

Besides, equipment trend management can allow the client to use blowers more safely.