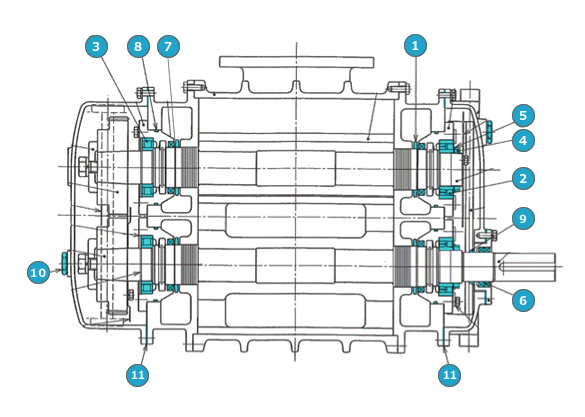

Need for Blower Maintenance

Blower appears rigid body like a steel rock, but it contains several sensitive components inside in order to secure smooth rotation, such as bearing, oil and seals. Those components are gradually worn-out or deteriorated due to raised temperature, friction and vibration caused by mechanical rotational motion. Even it is stored without any operation, deterioration could be occurred. If continuing operation under worn-out/deteriorated condition, it may cause unexpected sudden trouble and failures that will take huge cost and time to repair. Since blowers are essential equipment for running plants, long-time malfunction will result in severe impact on customer production activities. The best way to protect customers from these troubles is to conduct “regular maintenance”. Please be aware of counting on our maintenance service to use the blowers for a long time, conveniently and safely.

List of blower consumable parts

|

|

|

As well as bearing, blower has many rubber parts which are required to be replaced to new ones.

Overhaul work

|

|

|

|

Example of damaged parts without maintenance.

|

|

The value of maintenance

Generally, maintenance can prevent risks of failures and clarify the device situation, which allows you to secure the performance and extend its life.

|

|