About Blowers

|

|

What is a blower?

Blowers have two types of usage; function on the exhaust side with positive pressure or vacuum pump with negative pressure from suction side.

|

|

Function principle of Rotary Blower

| Two rotors rotate in opposite directions inside the casing. The casing and rotors do not touch each other and keep a small clearance between them while rotating. The gas (volume) enclosed by the casing and rotors is transferred from the suction side to the discharge side. This method is so-called “volume displacement blowers”, which main features are;

|

| Pressure difference is allowed between suction side and discharge side because it is physically separated by rotors. And this works for either;

|

History of blowers

These blowers are called Roots Blowers, taking the name from P.H. Roots, the initial inventor (USA Patent No. 2,369, reissued on October 2, 1866) of the LOBE pumps that became globally popular in the late 19th Century.While Japan manufactured blowers before the war, they became fully prominent due to the rapid increase in demand after the war. Manufacturers developed production technology, and the industry expanded from being valued at several billion yen to ten billion yen. In Japan, they are sold as “Rotary Blowers, Vacuum Pump (Roots Blower).”

| Blower structureThere is two types LOBE, two blades or three blades per rotor. And each manufacturer adopts individual own blade outline design, but there is not so significant difference.Blower has very simple structure composed by only two rotors, is easy for use, and has convenient feature of oil-free (Oil does not contact directly to the aero flow area). As the results, blowers have been long used for conveying gas for food, brewing, blower for chambers, agitation, cement, flour, and grain. Along with the request of higher pressure, multi-stage tandem connection system was devised. In 1948, new technology was developed to obtain high efficiency and vacuum by injecting a suitable amount of water into the casing. It was a revolutionary application as a vacuum pump for suction dehydration from each roll of paper production machines. |

| Expand the use for vacuum pumpVacuum pumps were invented to suck methane gas from inside coal mines to improve the maintenance, health, and environment inside the mines. As they helped prevent explosions inside mines, their usage became even more popular. With the development and increased reliability of mechanical sealing for shafts, these were incorporated to make handling various gases safer and easier. As a result, demand from petrochemical industries also expanded, creating a foundation for today’s gas blowers and vacuum pump markets. |

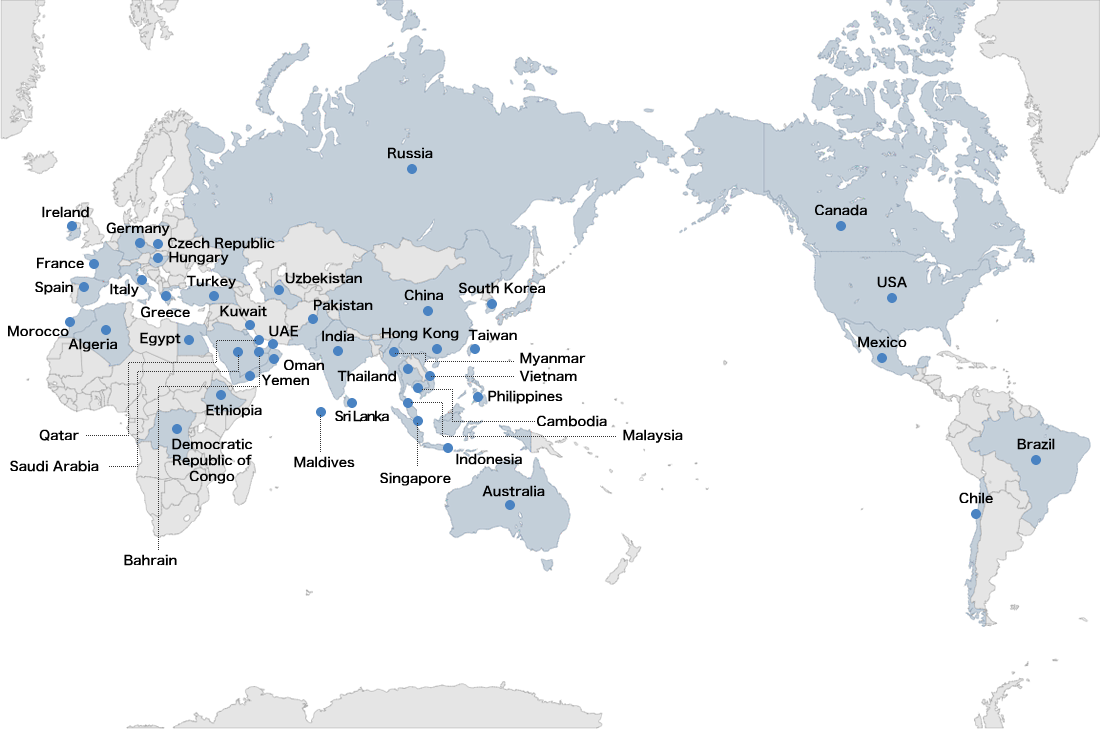

| Applications of blowersThe number of units produced for aeration and gas blowers increased even more as they rapidly developed after administrative standards were set, increasing public and private sector demands. Also, various measures were taken to deal with noise pollution regulations. In particular, the invention of sound deadening boxes and silencers resulted in the development of low-noise blowers, which became even more popular in various fields. As the company's scale expanded, the blowers manufactured in Japan currently range from small blowers with a 20mm bore to large blowers with a 700mm bore. They have been improved to sufficiently meet client needs of anti-acid and corrosion specifications by using various materials, such as cast iron, stainless steel, rubber-clad, and electroless nickel plating. As they are export-compatible, a large quantity of these products in various sizes are exported globally. |

Features of our blowers

Large blowersWe are capable to create large size models accordingly. The maximum nozzle size is 900mm, which is working as two-stage vacuum pump for PSA oxygen penetrators. Please get in touch with our sales representative for details. |

Procedure from inquiry to delivery

|

|

|

|

|